A Guide to Applying Labels

Tips for Applying Flawless Labels

Machine and Hand Applying

When you order labels with us, we will ask you if you are machine or hand-applying them. In the label printing process, how you will end up applying your labels is more important than you may realise. By considering factors such as label reeling orientation, surface preparation, and adhesive properties, you can master the art of label application and enhance the visual appeal of your products. If you want your labels to look flawless, here are some of our tips when it comes to the application of labels:

Hand Applied Labels

The attraction of applying labels by hand is the flexibility but it requires attention to detail and proper surface preparation. Paying attention to these 4 points will increase your chance of applying labels successfully.

Surface Preparation:

Before applying labels by hand, ensure that the surface is clean, dry, and free from any oil or grease residue. Proper surface preparation is crucial for achieving a strong adhesive bond between the container and the label and preventing label detachment.

Glass Surfaces Consideration:

When applying labels onto glass surfaces, be mindful that even seemingly flat and smooth glass surfaces is likely to have imperfections. We would recommend that you carry out a sample test before ordering, especially with clear labels, to assess potential issues such as bubbling. In some cases, using a paper label may turn out to be more suitable for glass surfaces.

Moisture Avoidance:

Any form of moisture can hinder label adhesion and the effectiveness of the adhesive. If moisture is unavoidable in your application environment, consider using labels with a stronger adhesive to ensure secure attachment.

Handling Adhesive Side:

Try to avoid touching the adhesive side of the label, especially with oily or unclean hands. Touching the adhesive side can affect adhesive properties and may leave fingerprints, particularly noticeable on clear labels applied to glass surfaces.

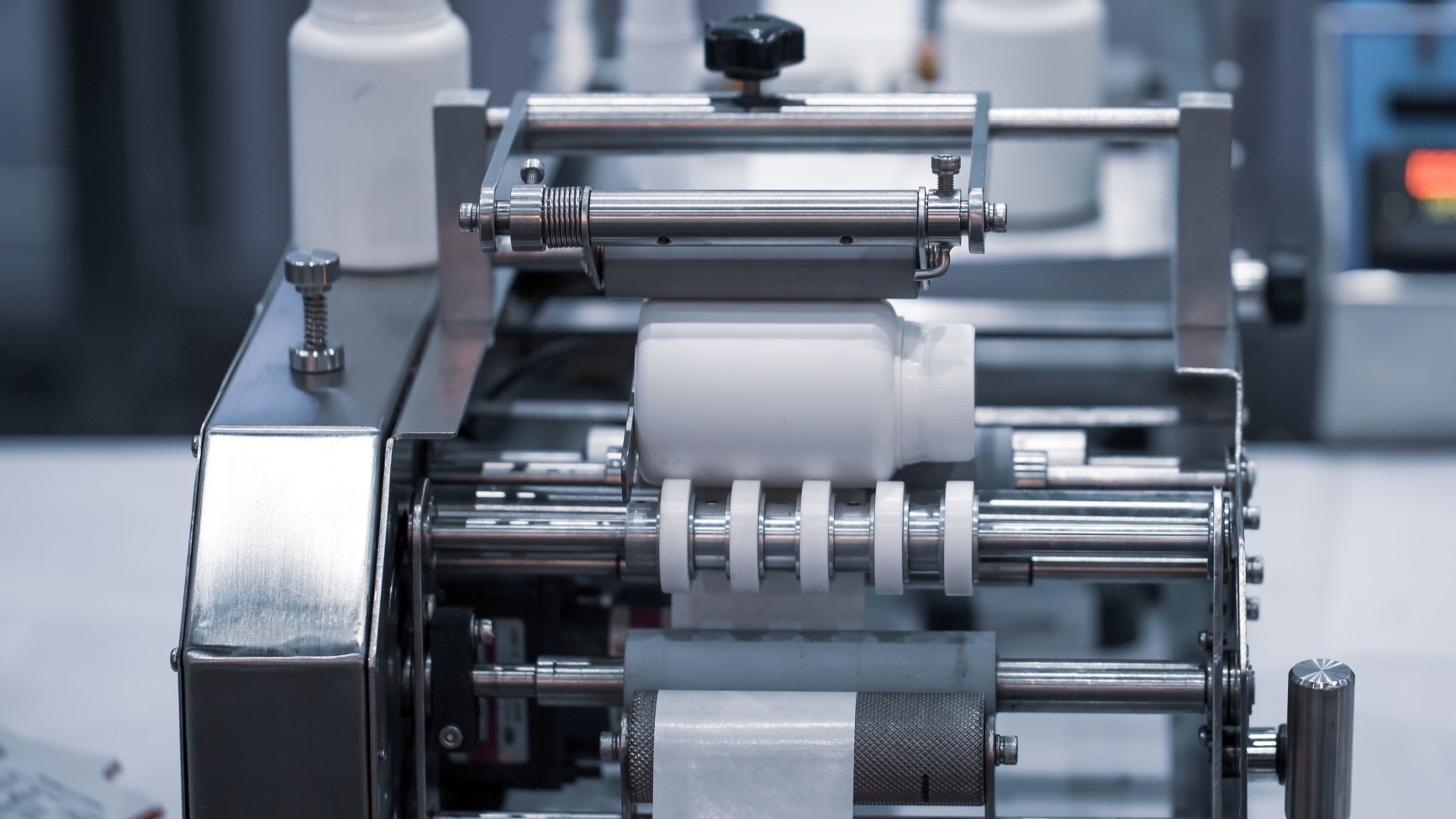

Machine Applied Labels

If you are using a labelling machine for application, attention to detail is paramount to achieve optimal results. Here are key factors to consider:

Label Reeling Orientation:

It is essential to determine the correct orientation for label reeling based on your labelling machine's specifications. You will need to identify the appropriate direction for labels to come off the roll and supply us with this information. The image below gives you some idea of how labels come off the roll.

Core Size:

Choosing the correct core size ensures that the labels are properly loaded onto the machine's applicator mechanism and fed through the labelling system without issues such as slippage or misalignment. Label cores come in various sizes, typically ranging from 1 inch to 3 inches in diameter (core size in the context of labels refers to the diameter of the core around which label material is wound into a roll). Matching the core size to the specifications of your labelling machine is essential for seamless operation and optimal label application. Some machines are designed to accommodate a standard core size, while others may require a custom core size to ensure smooth operation during the labelling process.

Specific Reeling Instructions:

Some labelling machines may have specific reeling instructions or preferences. Be sure to familiarize yourself with any additional guidelines provided by the manufacturer to optimize performance and efficiency.

In the world of product packaging and branding, the application of labels plays a crucial role in conveying information and making a visual impact. Whether you're using a labelling machine or applying labels by hand, there are important considerations to ensure labels look professionally applied. Attention to detail is key to achieving professional results.

Still not sure how to achieve professionally applied-looking labels?

At inkREADible, we understand the nuances of label application and are here to provide expert advice to our customers. We are committed to providing top-quality labels and expert guidance throughout the whole label ordering process. For assistance or inquiries about which labels best suit your needs, feel free to contact our team.

Let's elevate your product packaging with precision and professionalism in label application!